Why Heavy Fabrication from us:

The fabrication works took a longer period to complete until a few years ago, while they are being fabricated in a shorter amount of time, resulting in a handsome amount of costs savings.

Heavy fabrications steel products are engineered for large projects to achieve high quality and speedy constructions at optimal cost. The entire fabrication process starts with a design that is technically interpreted by engineering team and broken down in detail into shop fabrication drawings through 3D modelling by state-of-the-art Tekla software and then then electronically fed via DXF files to CNC machines.

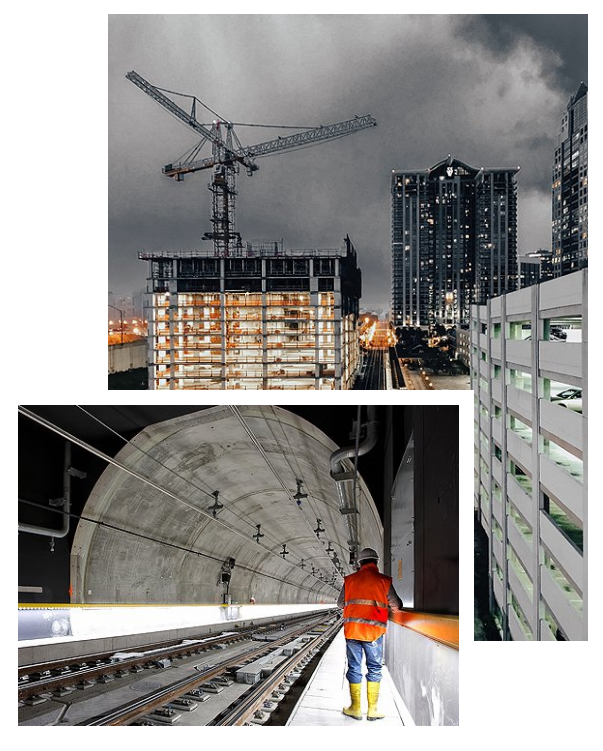

We deliver custom-designed solutions from designing to erection stage for all sectors including heavy industries, refineries, power plants, steel plants, cement plants, onshore oil & gas, petrochemical, high-rise buildings, airports. We are the most innovative & preferred partner with the widest range of products & services, including tailored beams, hot rolled, welded steel, H-Type beams, I type beams, trusses.

Raw materials are procured from all major HR plate manufacturers along with MTC & other required certificates as per the industry practices. In our pursuit for excellence in manufacturing heavy fabrication works, our facilities consist of state of the art CNC plasma & oxy-fuel cutting machines to cute webs & flanges at the required lengths, automatic submerged arc welding lines, CNC controlled drilling options, automatic twin head welding machines, 3D multi axis drilling machines to simultaneously drill holes in webs & flanges, automatic lines to carry WIP load, matching overhead cranes & support equipment’s, clean surfaces of steel materials upto SA 2.5 or higher grade, painting booths.

We do welding quality tests, stage-wise inspections and audits by our quality team and our testing labs are capable of doing DT & NDT tests. All the fabricated building materials are loaded and delivered to site building-wise/ phase-wise in erectable sequences. Our heavy fabrication works are more mechanized, systematic, process and output driven to match project timelines.